- Contact

- (+45) 70 27 87 00

3 million tons end-of-life tires (ELT) are collected every year across the EU countries. But the way they are processed is far from optimal. Although most of ELT are recycled, one third are still incinerated for energy purposes. These ELT are treated as waste instead of the valuable resource they are.

The consequences of not recycling ELT, is continued dependence on non-renewable resources such as oil and extensive CO2 emission to manufacture rubber-based product such as tires and conveyor belts. This creates not only climate and environmental challenges, but it is also a poor economic model, as valuable materials found in ELT tires are lost.

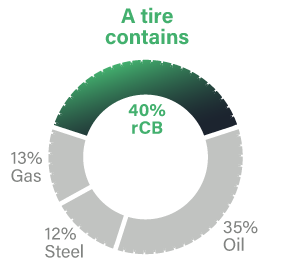

Many have been in search for economically viable alternatives to the incineration of ELT and Elysium Nordic will change this situation from 2024 by using a thermal decomposition based on a patented microwave technology to recover from ELT materials such a gas, steel, oil and especially carbon black, which is a material that is irreplaceable in the production of tires and other rubber-based products.

The first plant will be built in the port of Nyborg in Denmark with capacity to recover up to 12,000 tons of carbon black from 30,000 tons of ELT. The plant is the first important step towards a more circular, sustainable and reasonable approach to handling ELT.

Instead of producing new carbon black from oil, we can recover the carbon black from end-of-life tires (ELT. Carbon black is recovered through thermal decomposition by advanced microwave technology, where the ELT are heated in an oxygen-free environment thereby separated into oil, gas, steel and carbon black.

The plant will be able to use the recovered gas in the process itself, reducing the need for external sources of energy, as well as to

deliver surplus heat to the district heating network. The oil, which partly comes from natural rubber, will be supplied as a bio-oil, and the steel and carbon black will be supplied for recycling in new products.

The recovered Carbon Black (rCB), will consist of the same grades already present in the ELT. The quality of the rCB will be comparable to newly produced carbon black and can therefore be used as a full replacement in several applications.

Elysium Nordic was developed by a team with complementary competencies and decades of experience in business and project development, design, construction and operation of sustainable energy projects. This allows for a flexible, agile and to focus on the most valuable projects.

Elysium Nordic works with close-knit partnerships and use our well-established network in the industry to develop and implement new green installations.

Focus is on partnering with operationally skilled and technologically advanced strategic companies with a proven track-record. We put great emphasis on ensuring strong alignment with our project partners and a clear split of risks and responsibilities through a credible and transparent process.

Elysium Nordic is positioned in well-regulated markets with focus on de-risking. We develop high quality assets where governance and contract structures are well defined, and projects are executed in collaboration with best-in-class partners.

Recycling investments based on commercial market conditions have potential for visionary investors. Elysium Nordic will support corporate and institutional investors to fulfil their reallocation of investments towards renewable and sustainable assets.

The 17 UN Sustainable Development Goals are a call for action by all countries – poor, rich and middle-income – to promote prosperity while protecting the planet and people around the world. We support this at Elysium Nordic. Of the SDG’s we strive to create specific results within the following goals: