- Contact

- (+45) 70 27 87 00

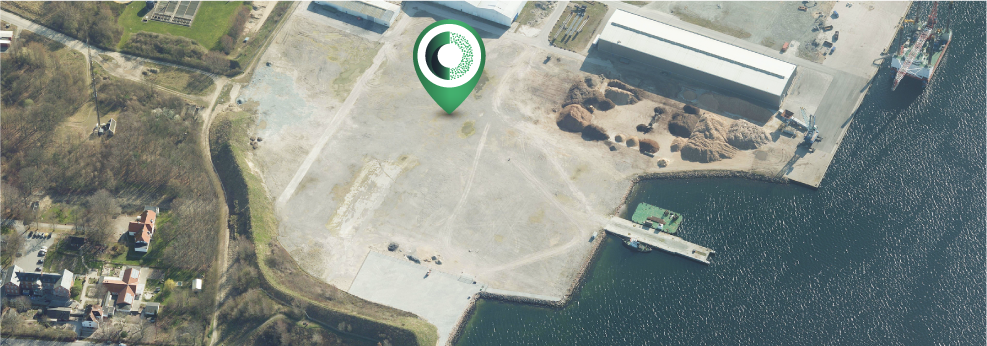

Nyborg is located on the west side of Funen in Denmark next to the Storebælt bridge. The plant is located on a harbor site, 300 meters to the highway (E20) which connects to the rest of Denmark and Central Europe. This makes it an optimal location for transportation of the sourcing of tires and for the end-products to costumers.

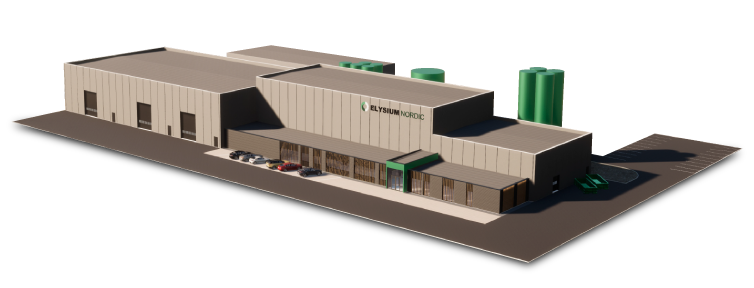

The plant will be on a 12,000 sqm area at the harbor, consisting of one production building and one ELT storage building.

The project has an option to rent the neighbour area, which gives the possibility to expand the capacity of the plant.

The project has obtained building and environmental permits and has moreover good relationship with municipality and coming neighbours.

Nyborg already hosts several industrial plants, which allows the project to access industrial suppliers and skilled workers.

The Elysium team developed the project over the past years, choosing site and suppliers, preparing and developing the plant in Nyborg, securing permits and licenses. Elysium Nordic is responsible

for overall project commercialization including negotiations, off-take agreements, construction, planning and management as well as operating arrangements during final stages of development.

Plans include start of construction after financing has been achieved and commissioning and testing through 2 to 3 years after respectivily, where the plant is expected to be fully operational.

The Elysium team will be managing the full construction process in cooperation with suppliers and experienced consultants and engineers. Care is taken to execute on all suppliers and interfaces and secure the productivity and safety of the plant.

During operation, Elysium Nordic will treat 30,000 tons of ELT every year. Through an ingenious technology ELT will be exposed to microwave energy and carbon black, steel, oil where gas will be recovered. At full capacity, the plant will produce up to 12,000 tons rCB. The rCB is pelletized and shipped to be used in new rubber or plastic products. Also recovered 10,000 tons oil and steel will be used in new more sustainable products. Together with our partners, we will collaborate to achieve the best possible environmental results.