- Contact

- (+45) 70 27 87 00

3 million tons end-of-life tires (ELT) are collected every year across the EU countries. But the way they are processed is far from optimal. Although most of ELT are recycled, one third are still incinerated for energy purposes. These ELT are treated as waste instead of the valuable resource they are.

The consequences of not recycling ELT, is continued dependence on non-renewable resources such as oil and extensive CO2 emission to manufacture rubber-based product such as tires and conveyor belts. This creates not only climate and environmental challenges, but it is also a poor economic model, as valuable materials found in ELT tires are lost.

Many have been in search for economically viable alternatives to the incineration of ELT and Elysium Nordic will change this situation from 2024 by using a thermal decomposition based on a patented microwave technology to recover from ELT materials such a gas, steel, oil and especially carbon black, which is a material that is irreplaceable in the production of tires and other rubber-based products.

The first plant will be built in the port of Nyborg in Denmark with capacity to recover up to 12,000 tons of carbon black from 30,000 tons of ELT. The plant is the first important step towards a more circular, sustainable and reasonable approach to handling ELT.

The current system is no longer working for businesses, people or the environment. We take resources from the ground to make products, which we use, and, when we no longer want them, throw them away. Take-make-waste. We call this a linear economy and today still 92% of the global economy is like that and it is clearly unsustainable.

The linear economy has to change. We must transform all the elements of the take-make-waste system: how we manage resources, how we make and use products, and what we do with the materials afterwards. Only then can we create a thriving economy that can benefit everyone within the limits of our planet.

Europe’s current, linear, growth model depends on finite resources, exposing countries to resource volatility, limited gains in productivity, and huge loss of value through waste. Ellen MacArthur foundation´s 2015 report Growth Within identified that transition to a circular economy in Europe could add €900 billion to GDP by 2030, increase household income by €3,000 a year, and halve CO2 emissions compared with current levels. Businesses, governments, cities and academic institutions have begun to explore these opportunities and are increasingly engaging in circular economy collaboration and innovation. With Elysium we want to participate actively to make our world more circular and thus more sustainable.

Instead of producing new carbon black from oil, we can recover the carbon black from end-of-life tires (ELT). Carbon black is recovered through innovative thermal decomposition by microwave technology from Canadian Environmental Waste International (EWI), where the ELT are heated in an oxygen-free environment and thereby separated into oil, gas, steel and carbon black.

The plant will be able to use the recovered gas in the process itself, reducing the need for external sources of energy, as well as to deliver surplus heat to the district heating network. The oil, which partly comes from natural rubber, will be supplied as a bio-oil, and the steel and carbon black will be supplied for recycling in new products.

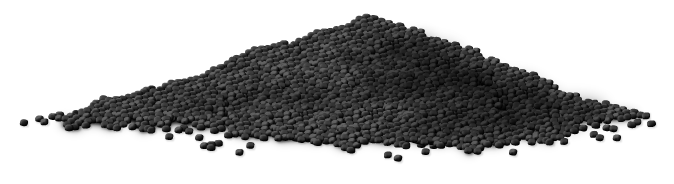

The recovered Carbon Black (rCB), will consist of the same grades already present in the ELT. The quality of the rCB will be comparable to newly produced carbon black and can therefore be used as a full replacement in several applications.

Carbon black is a fine black powder made of carbon. It is used primarily as a reinforcing material in rubber and tire products, but also as a key ingredient in the production of ink, different kinds of plastic, paintings and coatings.

Carbon black is produced from fossil fuels, mainly oil, by incomplete combustion in a controlled environment. The methods by which carbon black is produced depends on the grade and application needed.

Between 1,5 and 2 litres of oil is used to produce 1 kilogram of carbon black, which stresses the importance of recovering the carbon black that is available in our waste.

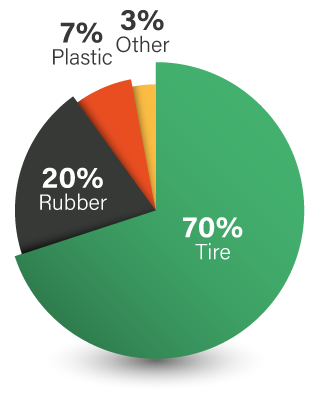

Left: Demand of carbon black per industry in Western Europe.

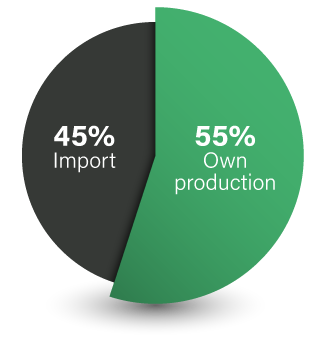

Right: Share of import and production of carbon black in the EU.

There is a strong demand for carbon black in the EU countries, and the demand is expected to continuously increase over the next years.

In 2018, total demand of carbon black in the EU countries was close to 2 million tons of which 45% was imported, mainly from

Russia and Ukraine.

The high share of new carbon black imports is related to the strict environmental and safety regulations in the EU, which make production of new carbon black in the EU more expensive than in countries with less restrictive regulations.